As a prominent importer of steel, aluminium fence panels , raw materials, and accessories, we recognise that the construction industry is constantly evolving. Therefore, we take the lead in leveraging the latest technology available in the market to enhance and expedite ideas, ultimately saving you time, money, and expanding your creativity.

Our customers are the heart of our passion and unwavering commitment to progress together, creating opportunities for greater stability, control, and improved efficiency. By prioritising our clients' needs, we strive to provide tailored solutions that cater to their specific requirements, enabling them to achieve their goals effectively and efficiently.

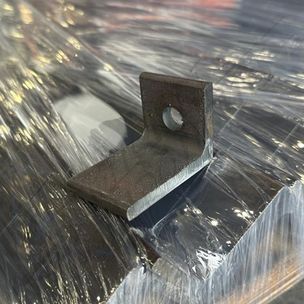

STEEL LUG | 75x50 | 8mm

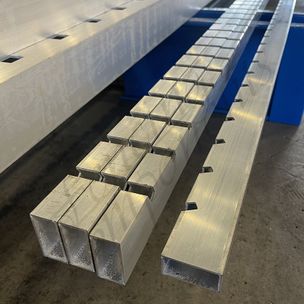

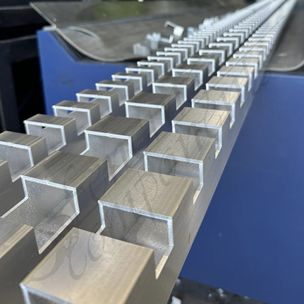

ALU | 100x100 | 3mm

STAINLESS | 33OD | 3mm

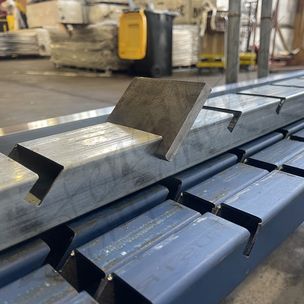

STEEL ANGLE | 50x50 | 1.6mm

STEEL | 19x19 | 1.2mm

STEEL | 65x65 | 2mm

ALU | 100x50 | 1.6mm

STEEL | 65x65 | 3mm

ALU | 40x40 | 1.6mm

STEEL | 50x25 | 1.6mm

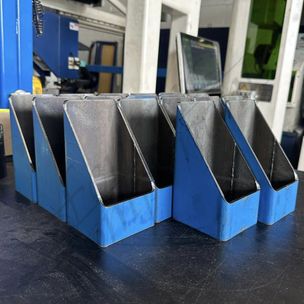

BLUE | 125x75 | 3mm

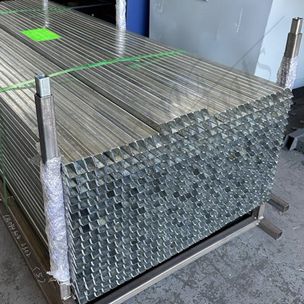

GAL | 100x50 | 1.6mm

ALU | 50x50 | 2mm

GAL | 30x30 | 4mm

ALU | 50x50 | 3mm

STEEL | 25x25 | 4mm

ALU | 50x25 | 1.6mm

STEEL | 150x100 | 5mm

STEEL | 25x25 | 1.3mm

STEEL | 75x50 | 2mm

BLUE STEEL | 80x40 | 1.6mm

ALUMINIUM | 2mm

STEEL | 40x40 | 1.6mm

STEEL | 50x50 | 2mm

ALU | 80x40 | 2.5mm

ALU | 80/40x40 | 1.6mm

STEEL | 100x100 | 3mm

STEEL | 40x40 | 1.6mm

ALU | 150x50 | 3mm

STEEL | 150x100 | 4mm

ALU | 100x75 | 1.6mm

STAINLESS | 19x19 | 1.2mm

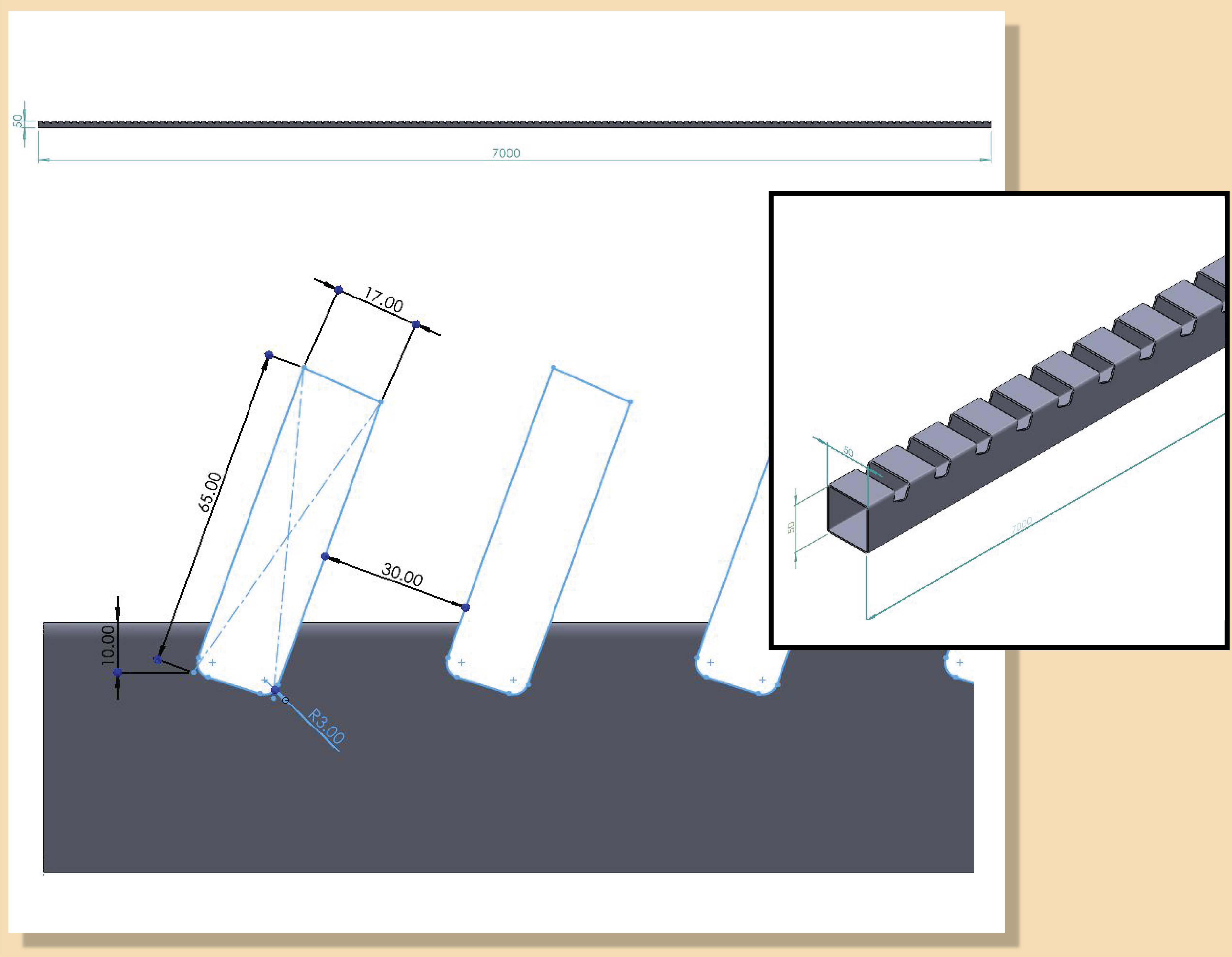

RAKED BLADE | 40x40 | 2mm

BLUE | 50x50 | 3mm

ALU | 50x50 | 3mm

Metal Laser Cutting Service in Sydney, Australia

At Fencing Components, we take immense pride in offering a comprehensive tubular metal-cutting service in Sydney, Australia that caters to a wide range of needs. Our specialisation in metal laser cutting has solidified our reputation as a top-tier choice for those who demand precision and quality in their metal fabrication projects.

In addition to our core services, we excel in crafting and to attending to a myriad of other bespoke metal solutions if you have the designs.

Precision and Accuracy in Metal Cutting

Our journey to excellence commences with the utilisation of advanced laser cutting machines.

We've invested in state-of-the-art laser systems that guarantee the utmost precision and accuracy in every cut. Whether you require laser cut aluminium, laser cut steel & stainless steel custom cut metal, our capabilities ensure that your specifications are met with perfection, delivering impeccable results for your project.

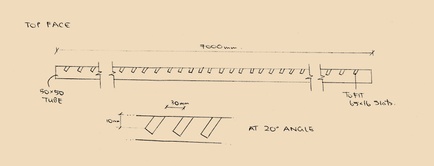

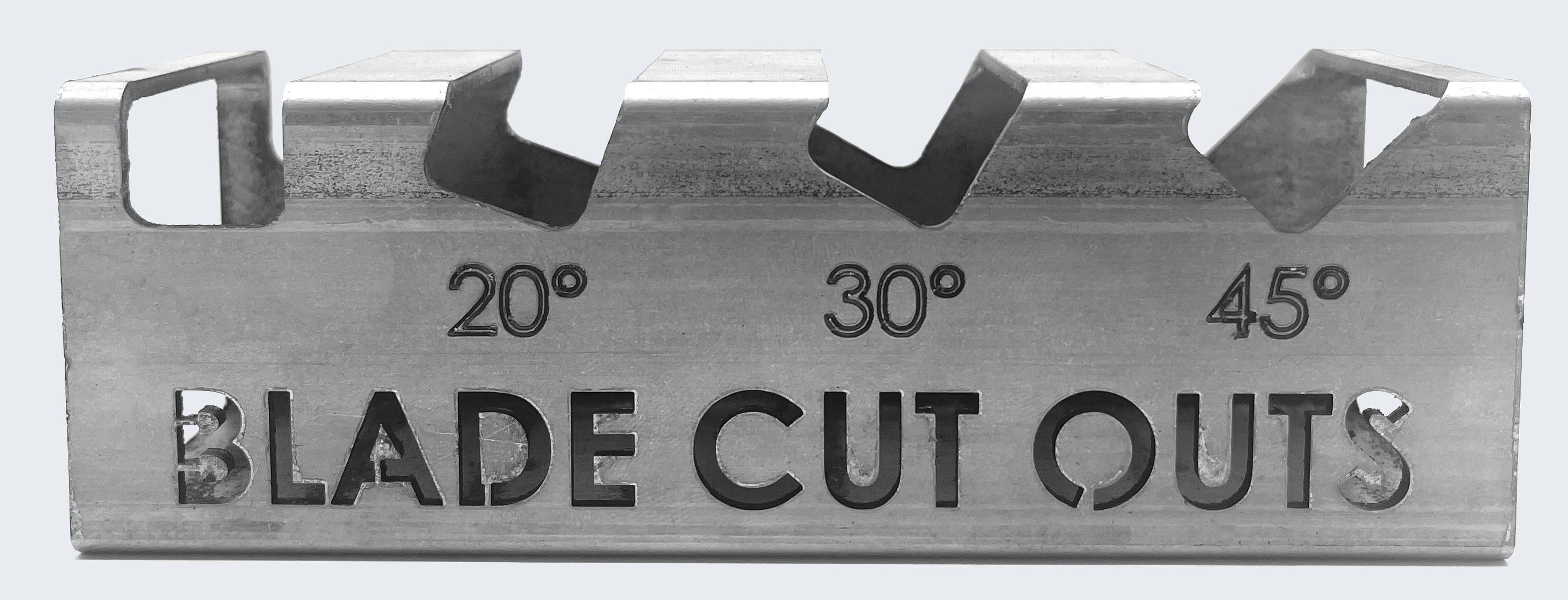

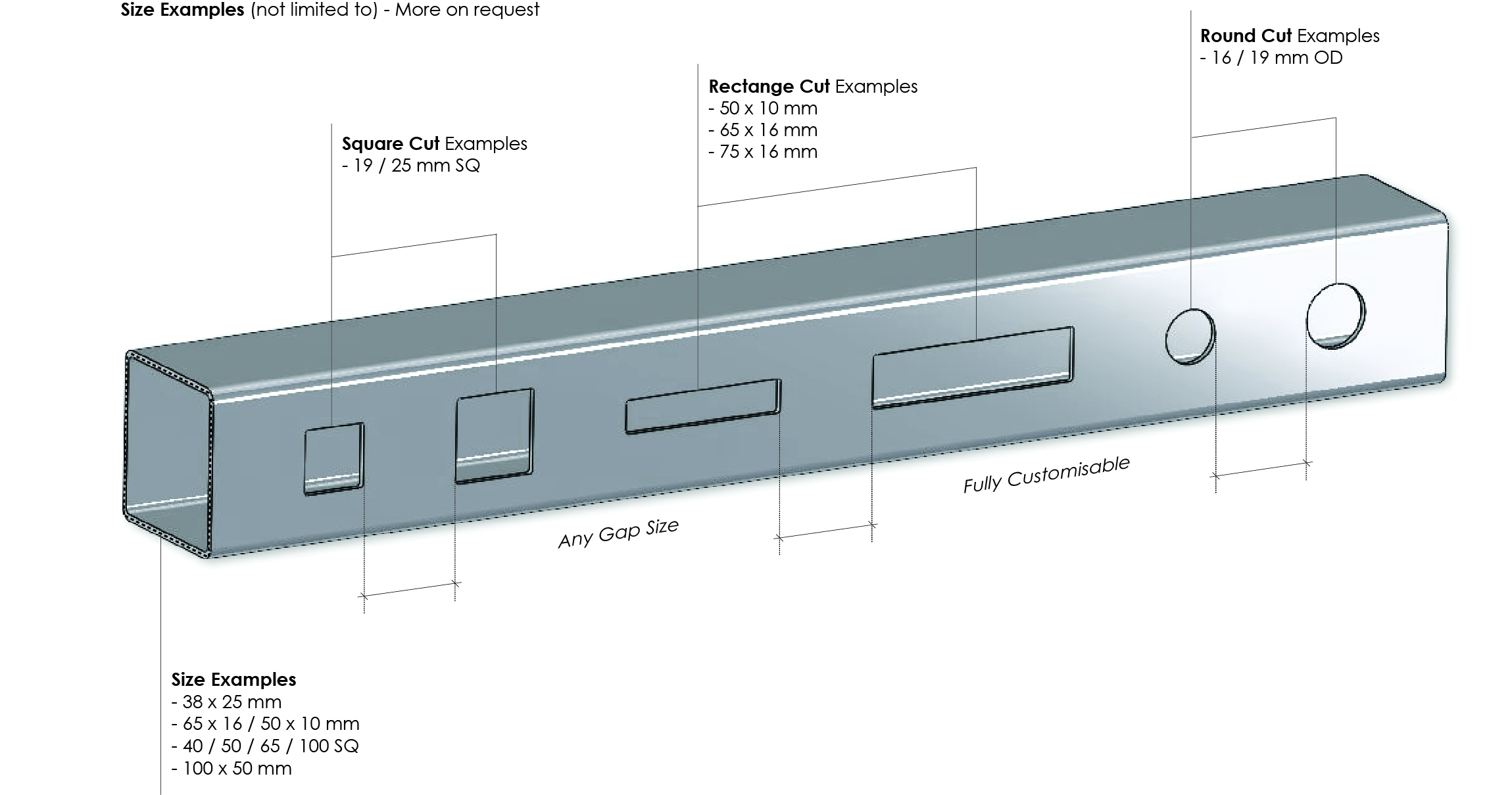

Simplified Cutting Guide Diagram

This diagram shows you basic tube sizes, holes and measurements that can be cut, more on request.

Discover more designs below!

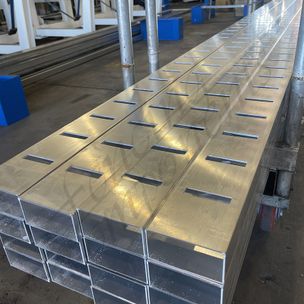

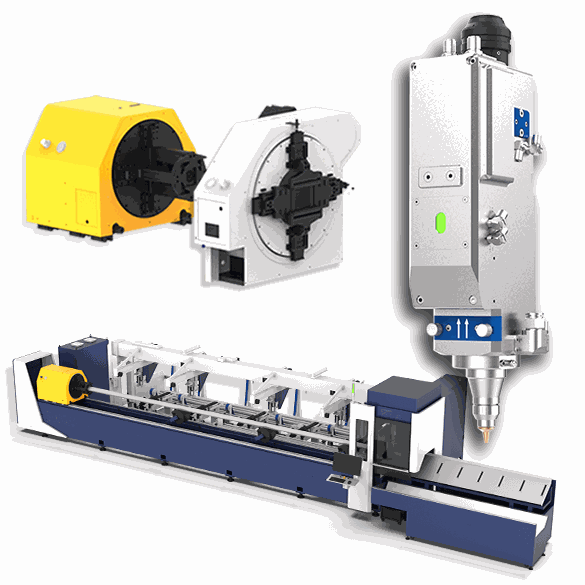

Automatic Loader & Laser Cutter

Quick Introduction and

Frequently asked questions

This laser tool offers you unparalleled flexibility. The efficiencies gained from automation and precision allows you to maximize your production workflow. Significantly reducing processing, handling and working time. Cutting down hourly rates required which directly results in cost saving, time efficiency and satisfied customers.

- Carbon Steel

- Aluminium

- Stainless Steel

- Square - 10-185mm

- Rectangle - 10-185mm

- Round - Up to 185mm

-

After final confirmation of specifications and design, lead time is usually 3-7 days to complete the job.

- Our automatic loader caters for high volume jobs allowing minimal downtime between tubes, shaving off crucial time in the cutting process.

- Yes! We welcome customer supplied material.

-

We can also provide with our huge range of locally stored materials or help source what you need with our intensive database and reach of material suppliers.

- Acquiring different tube profiles in a range of materials at a low cost is effortless.

- Yes, of course! Our dedicated design team will work with you on creating high quality specification drawings for your final approval, bringing your draft designs to a complete final product!

- Check out our design process, click here

- Yes! We have samples in our showroom, clickhere

Endless Possibilities

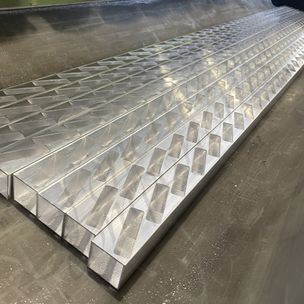

Laser cut tubes open up completely new avenues in design, free your design spirit and excite your customers with amazing design variants. Get inspired with more examples of our previous work.

Completed Jobs

Why Choose Fencing Components?

1. Sturdy Expertise

Our years of experience in the industry have equipped us with the knowledge and skills needed to handle even the most complex metal-cutting projects. We stay abreast of the latest advancements in laser cutting technology to provide you with the best possible service.

2. Cutting-Edge Equipment

Our investment in cutting-edge equipment empowers us to deliver precise and efficient metal-cutting services. We take pride in our ability to handle various materials, ensuring your project receives the attention to detail it deserves.

3. Timely Delivery

We understand the significance of timely project completion. Our streamlined processes and skilled team enable us to offer fast turnaround times without compromising on quality.

4. Competitive Pricing

We believe that high-quality metal-cutting services should be accessible to all. That's why we offer competitive pricing without hidden fees, ensuring you receive the best value for your investment.

5. Commitment to Sustainability

We are committed to environmentally responsible practices. Our laser-cutting processes are designed to minimise waste, making us a responsible choice for eco-conscious customers.

Your Trusted Partner in Metal Laser Cutting

Reach out to us today, and experience the difference of metal laser cutting with precision. Whether you need assistance with

aluminium fencing

,

fence posts

, or other custom metal cuts, our team is dedicated to drawing up designs and delivering high-quality metal cutting in Sydney to your requirements.

Don't hesitate to

contact us

for a consultation or a quote. We’ll get back to you as soon as possible.

Are you ready for the next step?

Click below for our Laser Cutting Form, email or call us to discuss further details and more information!

Call us!

The Latest Technology

Our FC High Precision Tubular Laser Cutting utilises the latest laser technology on the market. The auto-focus, full stainless steel cutting head functions dual path water cooling, focusing and collimating lens for the most precise cuts. Double Pneumatic Rotary Clamps are three times faster than electric chucks, with large and constant clamping force ensuring high cutting precision. Paired with an intelligent production line with automatic tube feeding, set up to handle high volume projects with efficiency, speed and accuracy.